Cetim Morocco supports you through a series of standardized tests and metallurgical analyses to determine the physical and mechanical properties of a metallic or composite material and its suitability for the intended applications.

In a demanding international regulatory environment, manufacturers must guarantee the quality and reliability of their products in the face of an ever-increasing number of innovative materials that are subject to severe operating conditions.

Whether you are launching a product, monitoring production quality, or dealing with a failure, you want to identify the mechanical and metallurgical characteristics of your materials in order to validate a design, ensure compliance with international standards, verify the reliability of your production process, or identify the causes of damage.

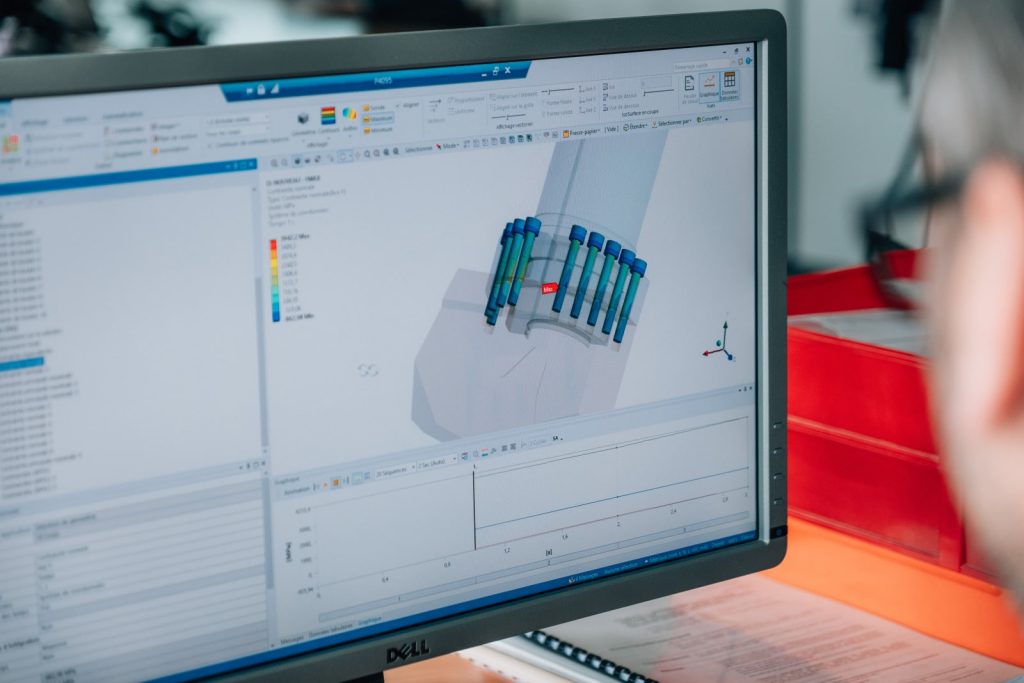

Customized testing: Our testing engineering experts design and implement multiphysics testing methodologies and protocols to meet your specific needs.

ASTM E8/ASTM E21/ NF EN 2002-1&2 / ISO 6892-1&2, NF EN 2002-5, ASTM E139 Accreditations/Qualifications: NADCAP, COFRAC, SAFRAN, AIRBUS & GENERAL ELECTRIC

DWELL tests on servo-hydraulic machines

Creep tests on servo-hydraulic machines

Relaxation tests

Cracking tests according to the test piece layout at room temperature and high temperatures (up to 900°C)

DaDn crack propagation: FC7, CT, KBR, and KB, etc.

K1C critical stress intensity factor test

Applicable standards: ASTM E606; ASTM E466; ASTM E647; ASTM E399

Accreditations/Qualifications: NADCAP, COFRAC, SAFRAN, GENERAL ELECTRIC

Analysis and chemical composition of metallic materials

Mechanical properties of metallic materials

Metallographic examination of metallic materials

Custom test bench engineering

Applicable standards: ASTM E112/ASTM E47

Accreditations/Qualifications: NADCAP, COFRAC, SAFRAN, GENERAL ELECTRIC

Identification and verification of the content of elements present by:

– Direct analysis of solid materials by Optical Emission Spectrometry (OES)

– Analysis after solution preparation by Plasma Emission Spectrometry (PES) Gas content measurement using various elemental analyzers to quantify hydrogen, oxygen, and nitrogen content

– Analysis and characterization of numerous metals and alloys (high-alloy steels, cobalt alloys, nickel alloys, titanium alloys, aluminum alloys)

Applicable standards: ASTM E1447

Accreditation/Qualification: COFRAC, SAFRAN

NEUTRAL AND INTERNATIONALLY RECOGNIZED EXPERTISE notably through various accreditations and customer qualifications

A UNIQUE PARTNER CAPABLE OF PERFORMING

all mechanical and metallurgical tests on the same site

LOGISTICAL SUPPORT particularly for international customers

EXTENSIVE TESTING RESOURCES and a Best Value service

AN INTEGRATED ORGANIZATION from test piece machining to test execution, offering optimum quality in the shortest possible time

Our experts support your teams in developing their skills through Cetim Academy® training courses to prepare for COFREND certification.

NADCAP accreditations, Cofrac testing, ISO 9001 and EN9100 quality management.