Subsidiary of the Technical Center for Mechanical Industries (Cetim France), Cetim Morocco offers a wide range of services and solutions specially designed to meet the needs of manufacturing industries in Morocco and Africa.

We focus primarily on key sectors such as aerospace, automotive, rail, energy, and process industries.

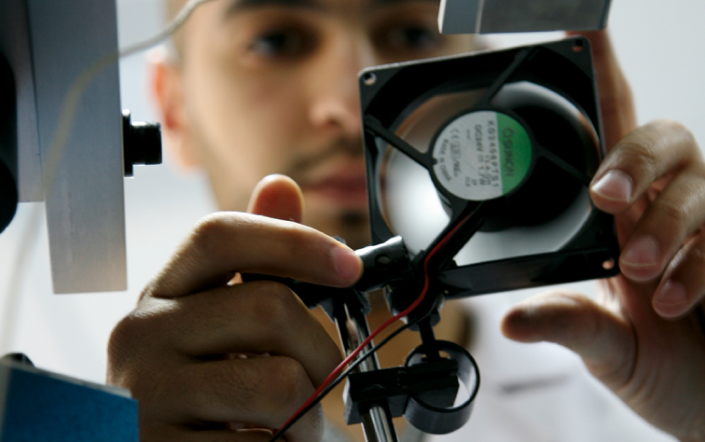

Testing and test engineering

Material characterization

Failure analysis

Technical and certification training

Inspection, Control, Measurement

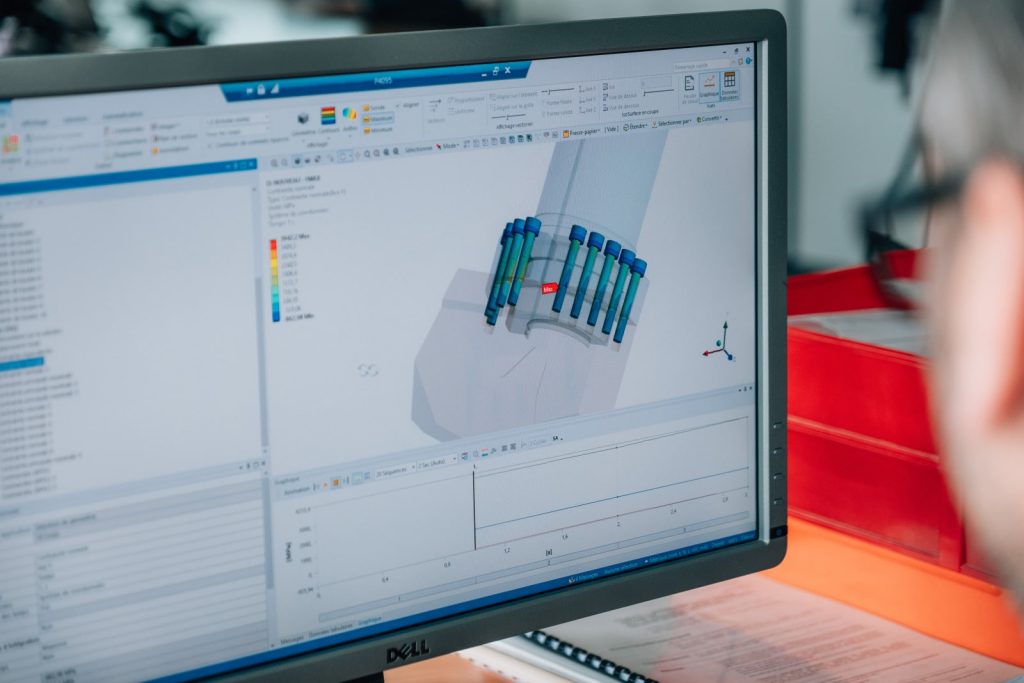

Numerical calculation and simulation

Consulting

drones, 3D scanners, robotization

to keep pace with changing business needs

Created in 2008, Cetim Maroc is the first concrete expression of Cetim’s commitment to international development in the field of high-tech testing. This strategic choice was made in view of Cetim’s relations with Morocco, with a view to providing new technological dissemination capabilities and fostering closer ties between mechanical engineering companies on both sides of the Mediterranean. Benefiting from Cetim’s decades of experience, Cetim Morocco has extended its range of services to the whole of Africa.

Creation of Cetim Maroc Developpement

Extension of the 3000 m² building and installation of new resources

Creation of Cetim Maroc Mécanique with a 2000 m2 extension

Located in the heart of Casablanca’s aeropole, Cetim Maroc’s aim is to support innovation and strengthen the competitiveness of companies, thanks to our multi-disciplinary expertise and unique R&D capabilities.

70 machines d’essais de fatigue 50, 100 et 250 KN à température ambiante et à haute température

4 machines de traction 1, 30 50 KN et 100 KN (température ambiante et à chaud)

5 machines de fissuration (température ambiante et à chaud)

19 machines de fluage rupture et allongement 20kN

1 machine composite

3 machines d’essais DWELL 15kN

17 microscopes optiques et binoculaires avec traitement d’images

2 microscopes électronique à balayage avec sonde

2 analyseurs d’hydrogène

6 machines pré-polissage, polissage automatique, enrobage à chaud et à froid

1 four de traitement thermique

DRX

1 machine N2O2

Cutting: six band saws, one disc saw, one composite saw, one sandblaster

3 wire cutters, 4 polishers.

Conventional machining: 5 lathes.

Digital machining: four lathes and two milling machines.

Grinding: one flat and two cylindrical

Control: 2D SCAN machine, non-contact measurement, marble, binocular, profile projector, roughness tester with all dimensional control equipment.

NADCAP accreditations, Cofrac testing, ISO 9001 and EN9100 quality management.